|

|

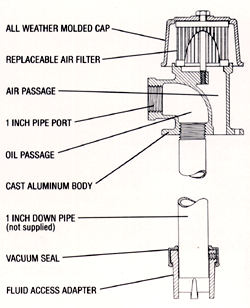

The OILMISERTMFILLorDRAINTM

features a cast aluminum body, and comes in two designs. The "tank mounted"

version, has a bottom flange, using the conventional filler/breather (6

Hole , 2.88 inch bolt circle) mounting patern. The "drum mounted" version

has a 2 inch NPT male pipe thread, and mounts directly into the 2 inch

pipe bung on a standard oil drum.

A 1 inch pipe is cut to the proper length, threaded on one end only, and then turned into the bottom port of the OILMISERTM FILLorDRAINTM. Next, the Fluid Access Adapter is located on the bottom end of the down pipe, just clear of the bottom. The complete FILLorDRAINTM assembly can now be mounted on the reservoir, replacing the original filler/breather. The OILMISERTM FILLorDRAINTM is much more than a conventional filler/breather. The extremely efficient, 5 micron air filter remains in place throughout the filling or draining procedure. A variety of Top End Couplers can replace the 5 micron filter and cap to accomodate most Spin-on and Desiccant Air Breathers As a filling device, the FILLorDRAINTM becomes a permanent filling wand, ideally suited to filter carts. Filling is at the bottom, below fluid level, eliminating turbulence and aeration. As a reservoir attachment, the FILLorDRAINTM is uniquely suited to adding kidney loop filtration to hydraulic reservoirs, and oilroom storage tanks.

JLM Systems Ltd.

|

The

cast body has two separate internal cavities.

The

cast body has two separate internal cavities.