|

On critical rotating

equipment,

oil sampling

has long been recognized as a prime indicator of mechanical condition

and

reliability. Most manufactures of gearboxes, drive train

components,

and hydraulic systems specify oil cleanliness levels in their warranty,

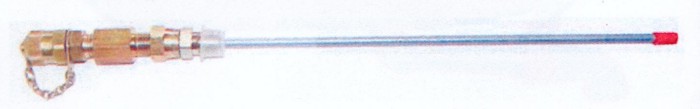

yet only few make provisions or recommendations for oil sampling.  Conventional

sampling tubes are sold as a "one piece" assembly which includes the

sampling valve (test point) with a permanently attached, 3/16" diameter

carbon steel pitot tube, and a

1/4" NPT male pipe thread.

Connection to the machinery is through a 1/4" female pipe port. Where internal obstructions interfere with

strait in-line access to an active oil zone, a pipe swivel is added to

the fixed assembly. This permits

a

limited degree of pre installation offset, prior to final

installation. When installed in a larger pipe port,

reducer bushings are required.

When using the conventional one piece sampling tube on Hi- or Lo-Viscosity applications, the main problem remains the highly restrictive inside diameter of the pitot tube. OILMISER™ Hi-Viscosity Sampling Tubes & Sampling Valves W

hen it comes to pulling an oil

sample, size counts. hen it comes to pulling an oil

sample, size counts. All OILMISER Sampling Tubes use a stainless steel pitot tube with a much larger 1/4" Inside Diameter. This feature lowers the flow resistance to heavier gear oils, and "significantly reduces" the time and effort required to draw an oil sample. Four times the inside area of conventional pitot tubes, means one quarter the effort. The OILMISER Sampling

Tube is a three piece assembly.

The three separate

components include the gland-se al

bushing ,

a stainless steel pitot

tube

and a gland-seal tube

retainer .

This configuration gives unparalleled

flexibility

to the OEM, the Service

Contractor and the End User. Now in a matter of minuets, a

sampling

tube and an oil sampling valve can be added to most gearboxes and

reservoirs

using

an existing top, bottom or side access port. al

bushing ,

a stainless steel pitot

tube

and a gland-seal tube

retainer .

This configuration gives unparalleled

flexibility

to the OEM, the Service

Contractor and the End User. Now in a matter of minuets, a

sampling

tube and an oil sampling valve can be added to most gearboxes and

reservoirs

using

an existing top, bottom or side access port.

Installing

OILMISER™

Hi-Viscosity Sampling Tubes

Like

all OILMISER Products,

the ease of installation in

the work place is the overriding

design

criteria for OILMISER Sampling

Tubes.

Once

the appropriate access port

on the

gearbox or reservoir has been determined, the gland-seal bushing can be

permanently installed.  In

some cases, internal

obstructions

may come into play. The exclusive OILMISER three piece design

maximizes

the amount of pre installation offset that can be accommodated.

The pitot tube is inserted into the gland seal bushing and

pre-formed. The gland-seal bushing and tube assembly is then

fed into the gearbox access port and fully tightened. Using

the OILMISER Tube Orientation Tool, the

pre-formed pitot

tube can be accurately positioned inside the gearbox. The

gland-seal tube retainer is then tightened, locating the pre-formed

tube in the correct location. In

some cases, internal

obstructions

may come into play. The exclusive OILMISER three piece design

maximizes

the amount of pre installation offset that can be accommodated.

The pitot tube is inserted into the gland seal bushing and

pre-formed. The gland-seal bushing and tube assembly is then

fed into the gearbox access port and fully tightened. Using

the OILMISER Tube Orientation Tool, the

pre-formed pitot

tube can be accurately positioned inside the gearbox. The

gland-seal tube retainer is then tightened, locating the pre-formed

tube in the correct location.All OILMISER Hi-Viscosity Sampling Tubes terminate in 1/4" NPT (female) pipe. Two configurations are available, strait in-line, or in a 90 degree swivel, giving a full 360 degrees of rotation. Now the final orientation of the sampling valve can address both the safety and efficiency of the service technician under operating conditions. Sampling valves are ordered separately.

JLM Systems Ltd. |

|